A brief first glance at the newly-unveiled Toroidion patent.

I’m at work now, so I’ll be brief.

Know Toroidion? Well, in case you don’t: Toroidion is a Finnish manufacturer of supercars. Last year, it unveiled its concept car prototype, with a whopping 1 megawatt total power. Or claimed power, to be specific. For car people, that’s roughly 1300 horsepower. In other words, quite enough for most purposes.

Of course, Toroidion claimed to have new revolutionary powertrains and motors. Insert your buzzword of choice here.

Patent application

Anyway, their patent application was recently made public (in Finnish at least), so here’s my first impression. This is all based on a very quick skim-through, mind you. Hence, mistakes are possible.

Here goes.

On the first glance, it seems that the claimed revolutionariness lies in parallelization. In other words, they took a permanent magnet machine with tooth-wound coils, and divided it’s stator into segments. Each segment has three coils in three-phase configuration. And here’s the catch: each segment is supplied with its individual converter plus a small battery pack.

Of course, this kind of configuration results in greatly reduced voltage and current rating requirements for each individual converter. And the same goes for the batteries, of course. On the flip side, you need more of them.

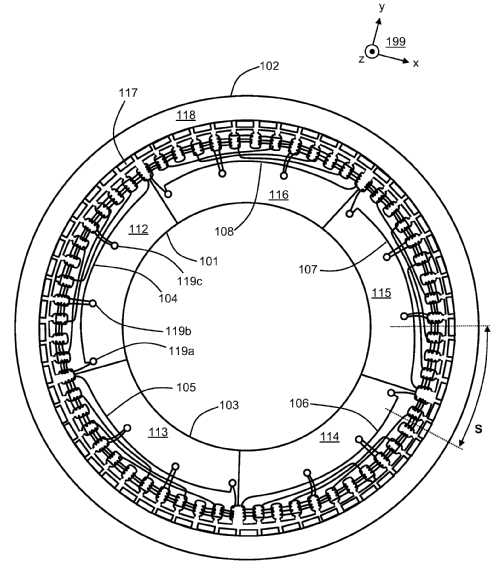

Then, the motor itself. To me, it looks like a fairly typical permanent magnet outrunner motor. Meaning that the stator is located in the middle of the machine, while the rotor is on the peripheral. This configuration is quite widely used for e.g. model helicopters. Anyway, take a look at this from the patent application.

The arrowed blocks are the permanent magnets, arranged in the typical ultra-high-pole surface-mounted configuration. The parallel winding configuration is represented by the black lines. In an extremely confusing and inreadable manner, in my opinion.

But I guess that’s like a fundamental requirement for a patent application.

The illustration for the entire motor is even worse, up to comical levels. Just take a look.

Your daily dose of negativity

Us Finns can be very pessimistic in nature. That’s true especially in online communications. I’ve been trying to avoid that, but I’ll make an exception here. Mainly because I can. Plus balance and all that.

So, here’s the bad.

1. Batteries

As pointed out here in a coffee room discussion this very morning, thermal aspects can be problematic. Converters and the motor itself are probably fine – they cool down quickly. However, if the bazillion small batteries are located in the same place inside the car…They can be difficult to keep away from meltdown. Especially if the claimed 1 MW power is true. Taking that much out of batteries of any reasonable size is somewhat hard, to say the least.

And they very likely are located in the same place. After all, the company claims that their batteries have a rapid-swap capability. That pretty much requires them to be located close to each other.

2. Three-phase coils? Really?

I hope this is just a simplified example and not something they’re actually limiting themselves to. I mean a three-phase winding is simple, and pretty much a minimum requirement for a smooth ride.

But, it’s not something you have to contend with. Machines with these kind of tooth-wound coils tend to suffer from high torque ripple. I saw a really nice presentation about this recently at EPNC. However, it can be greatly reduced by using more phases than three.

Which is something I think Toroidion should be doing, and hope that they are. I mean, they do have a million converters anyway. Since the power electronics is already there, you might as well make the best of use out of it.

Let me stress this:

More phases = more coolness.

3. Weird tooth shapes

Tooth-wound coils are often paired with rectangular stator teeth. This way, the coil can be wound elsewhere, and then just pushed into its place.

By contrast, the patent illustration suggests fairly narrow slot openings, requiring the coil to be wound in its final place.

But then, this may be just an illustration oversight, deliberate or not. Also, for a supercar, the cost of more elaborate coil manufacture may be negligible.

4. Marketing

Nothing to do with the patent itself, but needs to be pointed out.

Toroidion flat-out sucks in marketing.

Crappy videos. ’nuff said.

And their social media. Oh don’t get me started on that. Wait, too late.

Yeah, they are present in freaking everything. Any channel and medium you can think of.

And in all of this combined: zero interaction. Nil. Nada.

I mean come one, it shouldn’t be too hard to like a re-tweet or stuff like that? Right? It kind of makes you seem not like a complete arsehole.

Your daily dose of neutral

Is this really patentable?

Woah.

On the other hand, the design aspects are interesting.

How many parallel power paths to use? Lots and lots of aspects to consider.

Your daily dose of positive

It is an electric car with a freaking 1 MW power level. And it’s Finnish, so I do hope them all the best and millions in sales.

Edit: Winding Benefits

I’m slightly embarrassed I only realized this now. It was quite obvious, really. But then, I’m also a firm believer in admitting ones mistakes, so here goes:

The suggested parallel converter topology has one huge benefit for this kind of an application. You see, the motor has a huge number of poles, and will obviously be rotating quite fast at max vehicle speed. Normally, this would results in a staggering induced voltage (back-emf) per each winding turn. This is simply due to the fact that the air-gap flux density is completely reversed from magnet to magnet. As stated by Mr. Lenz, this leads to a large induced voltage.

For the frequency converter to survive this, a very low number of turns would then be required. (Unless a converter with an extremely high voltage rating was used.)

And, to keep the DC-resistance as well as the skin– and proximity effect losses in check, a stranded winding of some kind would be needed. Which would lead to circulating current losses, unless a Litz wire or a form-wound winding with transpositions was utilized (more expensive). And as we know, circulating current losses in high-speed machines can be quite huge indeed.

However, in this proposed topology, the flux linkage of each converter is only a fraction of the traditional value. This enables the use of a much higher number of turns in the winding, with the same converter rating. This is also simpler, and quite certainly has smaller total losses.

See ya,

-Antti

Check out EMDtool - Electric Motor Design toolbox for Matlab.

Need help with electric motor design or design software? Let's get in touch - satisfaction guaranteed!

Because every pole shoe has an individual coil, the number of stator poles and the number of phases are, in some sense, equal. It depends on the amount of intelligence controlling individual power electronics.

Perhaps the teeth are needle-wound, the pole shoe inserted separately, and individual teeth then assembled into a stator. One cannot escape the feeling that some sort of modular assembly is intended.

Hi Teemu, and thanks for your comment!

Yea you have a very good point: this kind of parallel topology really makes it possible to use all kinds of esoteric N-phase control schemes. Something that you literally can’t do with three-phase machines.

Also, thank you for bringing the winding back to my attention. It started me wondering about the number of parallel strands, circulating current losses, and such. This, in turn, made me realize those might be in fact un-needed, since the converter voltage rating is not a huge limiting factor any more (thanks to the parallel topology). Long story short, I appended my text by one subsection 🙂

Best,

-Antti

It’s a poor hypecar concept (pun intended..). Not a car, not a hypercar; just a shell to sell dreams and make money. No taste, no intelligence, no reality. Hype to raise money and then try and produce a few cars to sell to the hyper rich.

When the sht hits the fan there will be big trouble..

People who lose money because of lies don’t forgive easily..

Obviously I hope you’re wrong…but you do have a point.

Plus I love your username 😀

Is this quite similar to the “patent”:

https://www.google.com/patents/US8283831

The overall idea seems very similar. Probably that’s why Toroidion used four segments in their application rather than 3 like in your link 😀

Oh, and their application for a patent did not pass; they only got industrial design rights (or some close equivalent of that).